Vehicle Routing and Packing Optimization

Project Overview

Our Vehicle Routing and Packing Optimization system is designed to find the minimal number of vehicles for a given load, determine the shortest possible route for each vehicle, and perform optimal packing of orders based on the size and sequence of nodes to be visited. This solution addresses complex logistics challenges by combining advanced algorithms for vehicle routing, load optimization, and efficient order grouping.

Project Showcase

Key Features

- Vehicle list provided with capacity, dimensions, and cost

- 50 km radius around the warehouse for order fulfillment

- Order list containing weights, dimensions, and location coordinates

- Utilizes minimal number of vehicles daily based on orders and available vehicle list

- Groups multiple orders at the same node together

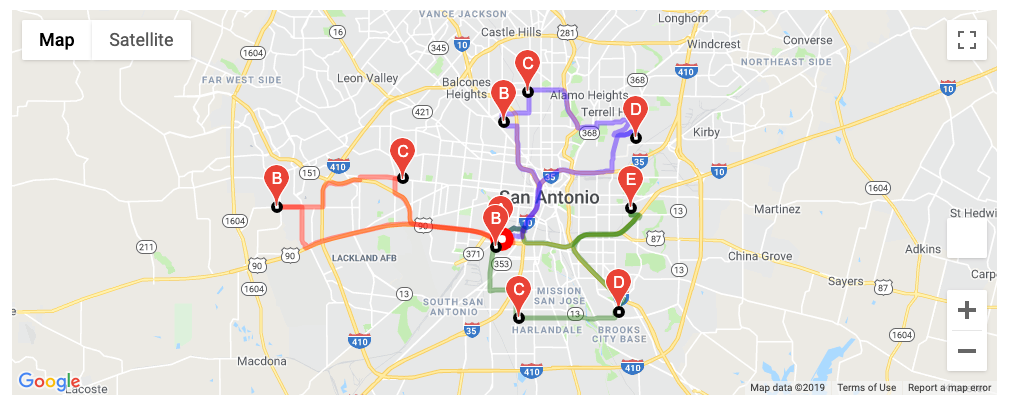

- Break available nodes into k groups which are nearby to each other based on distance

- Run a linear program to find the minimum number of vehicles for each cluster of nodes

- Combine the orders that belong to the same location

- Perform Capacitated Vehicle Routing Problem on each cluster

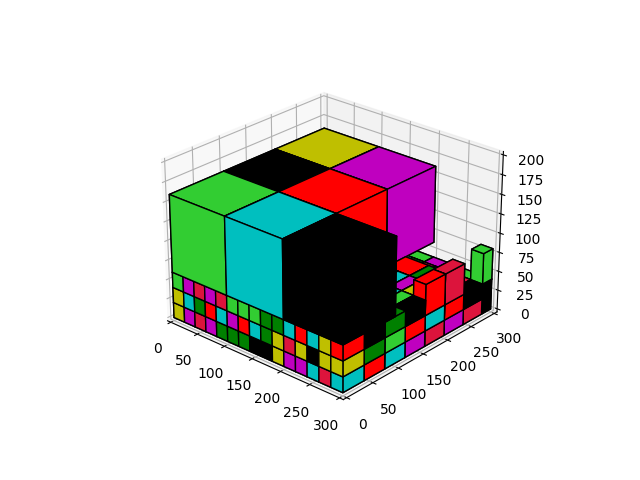

- Perform bin packing in each of the vehicles

- For 20 requests having 2000 nodes, it takes 75 seconds to perform the whole process for a single request

- Deployed on a cloud machine with 30 GB and 12 cores

Technologies Used

- Advanced algorithms for vehicle routing and bin packing

- Linear programming for vehicle allocation

- Clustering algorithms for node grouping

- Geospatial analysis for route optimization

- Cloud computing for scalable processing

Benefits

- Significant reduction in transportation costs

- Improved vehicle utilization and capacity management

- Optimized routes leading to reduced fuel consumption and emissions

- Enhanced order fulfillment efficiency

- Scalable solution capable of handling large-scale logistics operations

Project Status

This solution has been successfully deployed in production for a leading agritech company

For inquiries send a mail to